All manufacturers of OSB panels (Oriented Strand Board) in the construction sector they face problems of humidity and fire resistance. The research conducted in Germany by the SMS Group makes the positive results obtained with the electric arc galvanizing process available to OSB panel manufacturers.

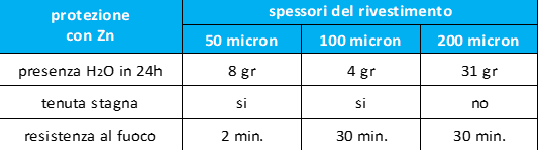

Zinc deposits, the 50 a 200 micron, they proved to be very effective:

- against corrosion due to ambient humidity, because zinc in contact with the environment is passivated forming ZnOx oxides which protect the underlying support;

- they stretch the fire resistance to more than 30 minutes because the ZnOx oxides begin to evaporate at 1,300°C (unprotected panels begin to burn at 230°C);

- protect people and environments from magnetic field interference.

A brief summary of the research results follows:

For those interested, we offer our experience and ours electric arc systems 300A – 400A – 600A.

for information: www.colimet.it – info@colimet.it