Zinc protects the aluminum from corrosion "pitting"

Growing use of aluminum at the expense of Copper: in the radiators of cars for its lightness and ventilation equipment, such as air conditioners, coolers and heat exchangers primarily a problem of costs since the Aluminum prices are equal to 1/3 those of Copper.

In the face of these positive aspects of the Aluminum has a weak point represented by corrosion from "pitting" (o vaiolatura) which it is overcome thanks to the deposition of a thin and uniform layer of zinc galvanizing with electric arc.

Zinc, less noble Aluminum, It acts as a sacrificial anode and spreads along the surface of the capillaries preventing the corrosion of the graft and its propagation in depth. In addition, the slight porosity of zinc makes the perfect surface for subsequent painting because the coating behaves like a sponge, creating a good bond with the underlying Aluminum.

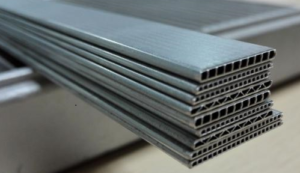

The spray galvanizing is commonly used in extruded multi-port (mpes), the thickness varies from 10-14 gr / m² depending on the needs of the customer.